Application

Experiment

Description

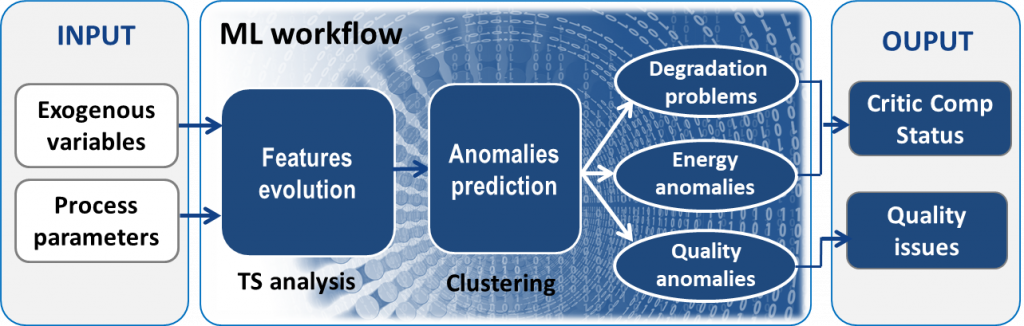

COGNINTEL relies on an integrated temporal domain (time series analysis) and spatial domain (unsupervised clustering) approach. This enables sharp enhance diagnostic and prognostic capabilities. While ensuring quick deployability, along with a high level of confidence, applicability & scalability.

Up to now a TRL 4 has been reached aiming up to TRL 6. The key SW modules prototype (Learner and Predictor) of the AI-based COGNINTEL platform will be improved. So that it can be fast deployed, flexible & scalable. As well as to ingest and cost-effectively process a consistent number of signal features with a high level of confidence & accuracy.

AE Results and Impact

The COGNINTEL experiment will deliver the following results to enable and prove a cost-effective deployment of CPES architecture / solutions.

Physical Layer

Data collection, data fusion, and data communication and/or connection implemented in demo facilities.

Cyber Layer

Data analytics and AI developments for highly confident diagnostics and prognostics. Quick deploy-ability and a high level of applicability and/or scalability implemented on a demo Server / Local (edge) workstation.

COGNINTEL platform

Validated against the defined KPIs for a CNC grinding/milling machine.

Methodology

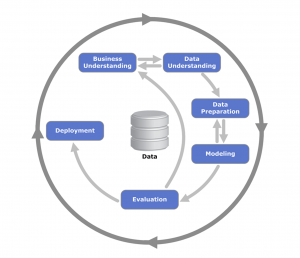

The COGNINTEL machine learning workflow relies on the CRoss Industry Standard Process for Data Mining (CRISP-DM) methodology. CRISP-DM is a process model with six phases that describes the data science life cycle.

The modular COGNINTEL implementation architecture includes a ‘Learner’ module (to train the model) and a ‘Predictor’ module (to deploy the model in production)

Application Scenario

Scenario 1

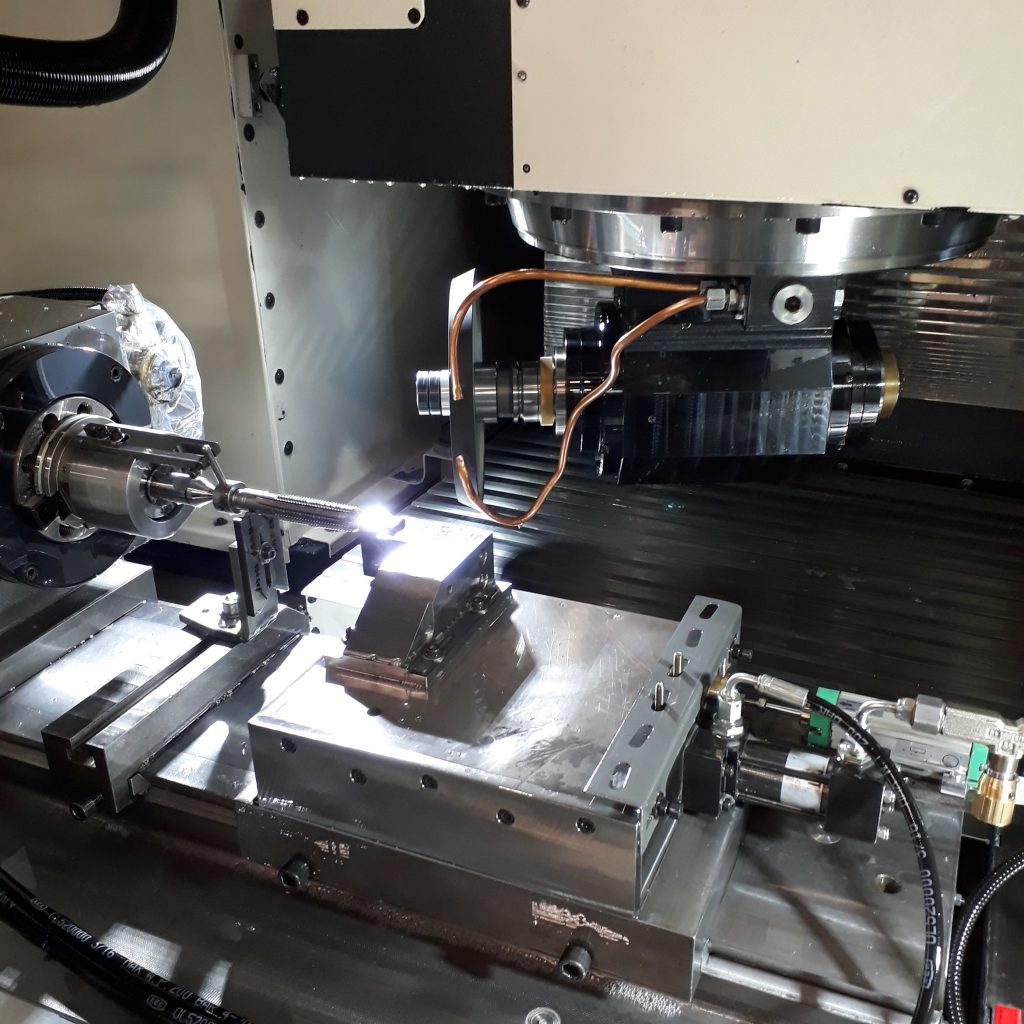

Pilot 1 – SCORTA use case: enabling a holistic and intelligent Quality, Energy and Maintenance management approach within precision manufacturing of thread cutting tools.

Scenario 2

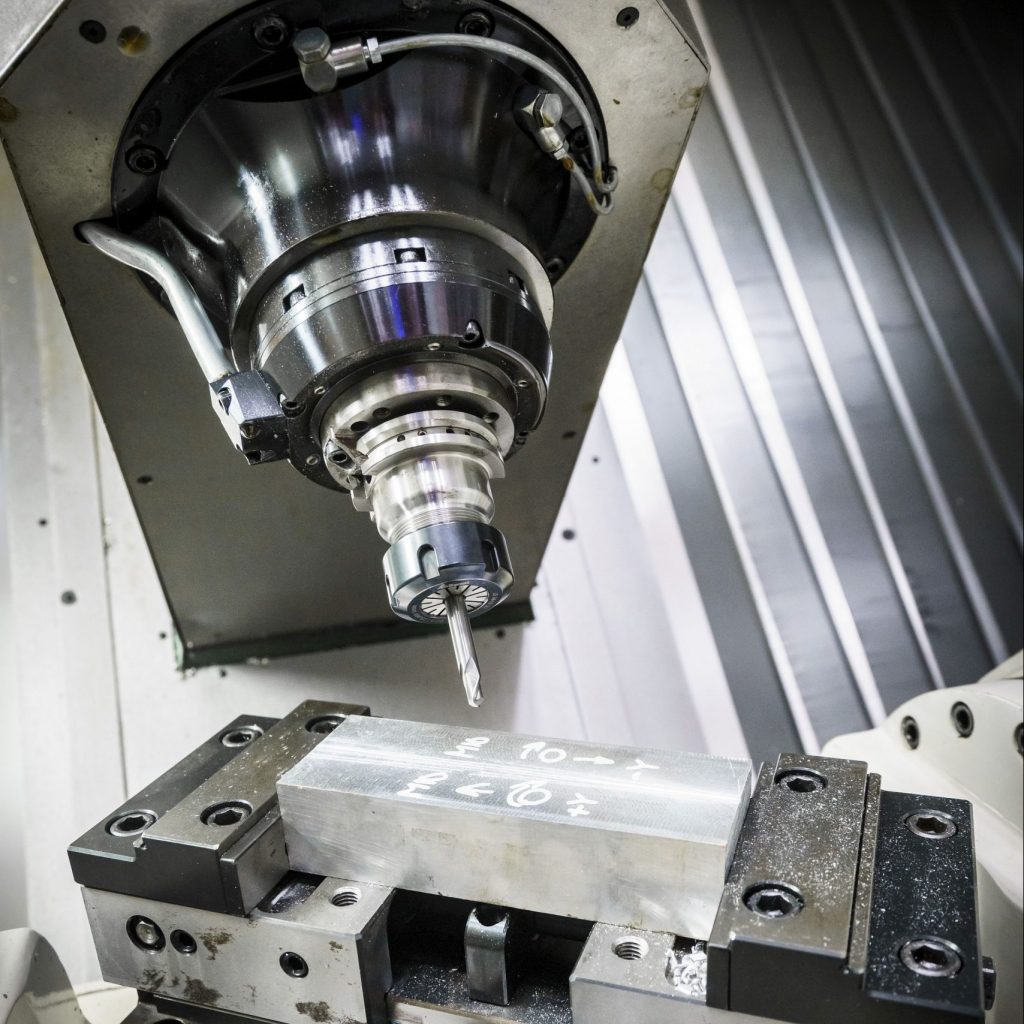

Pilot 2 – CIIRC CTU/ DIH use case: enabling a holistic and intelligent Quality, Energy and Maintenance management approach in precision drilling operations.