Use Case: CIIRC CTU/ DIH Scenario

QEM Management Approach in Precision Drilling Operations

Use Case Description:

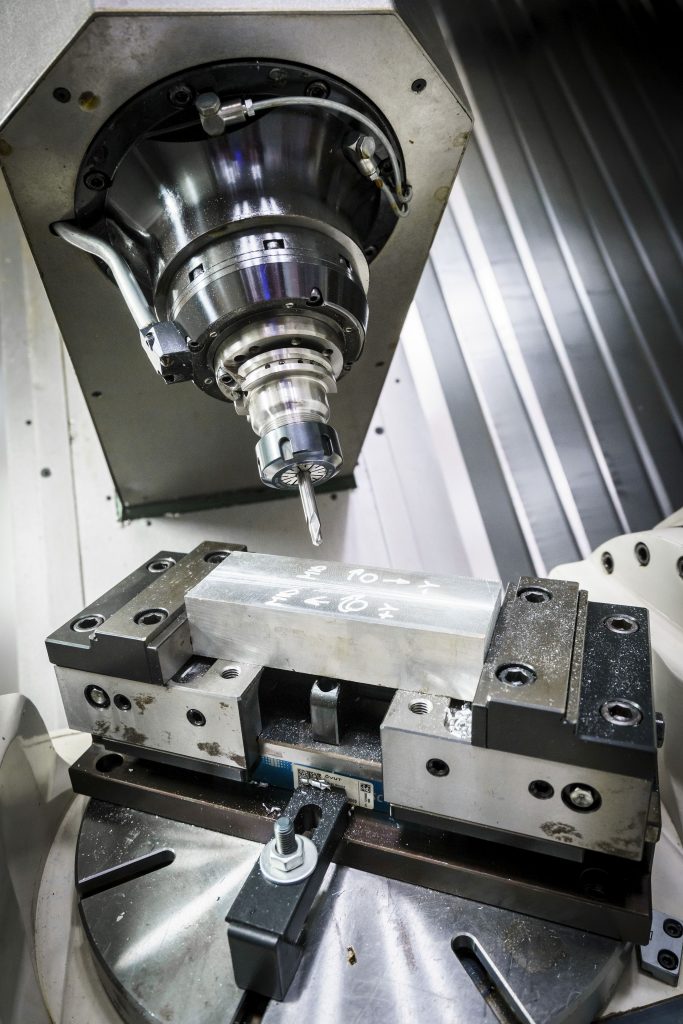

Focus on monitoring of tool wear during drilling operation:

- D6x10 mm hole, HSS spiral drill

- Tool steel material

- Hundreds of drilled holes

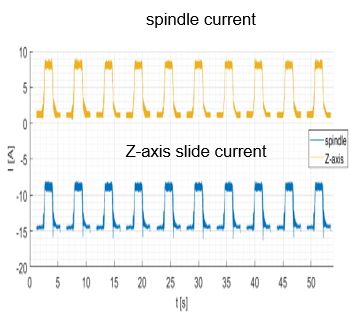

The goal is to capture signal variance with increasing tool wear.

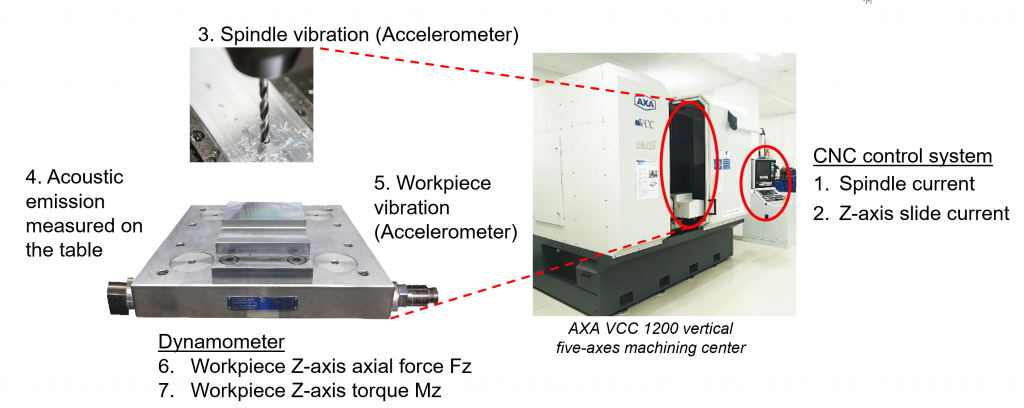

7 selected sampled monitoring parameters

As-Is State:

- Every drill is going to be worn during drilling. The worn cutting edge may cause vibration level change and increased cutting force.

- It is not generally known what real-time measurable variables and extracted features can characterize the tool wear appropriately.

- The key question represents optimal moment for tool change.

To-Be State

- Feature (combination of features) well characterizing tool wear is identified.

- Thresholds for tool change situation are identified and successfully applied.

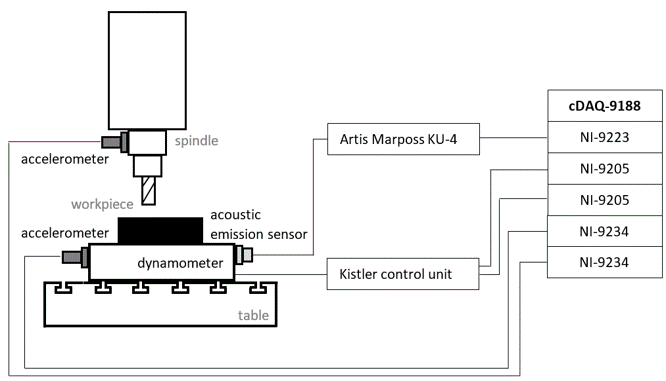

- Data acquisition based on National Instruments (HW, SW)

- Modular solution for fast adaptation, adding sensors etc.

- Possibility of CNC data synchronization (e.g. digital input reading)